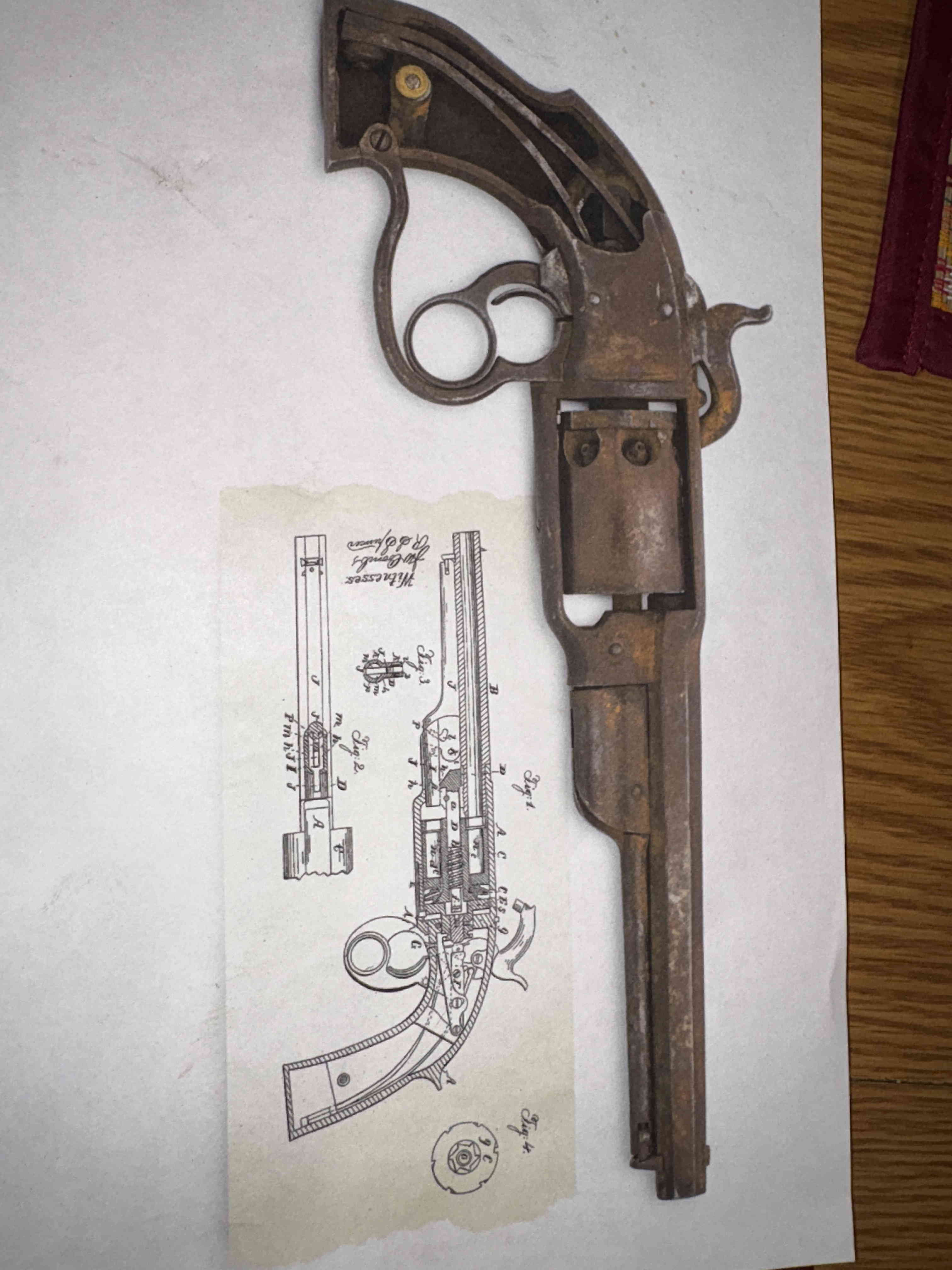

Restoration Report

Savage North 1861 Navy Revolver (.36 caliber cap and ball) – Lee Family Farm, Weatherford, Texas

1. Object Identification

| Object Summary | |

|---|---|

| Object Type | Percussion revolver (black powder) |

| Designation | Savage North 1861 Navy Revolver, serial no. 7884 |

| Country of Origin | United States |

| Date of Manufacture | c. 1861–1862 |

| Materials | Steel, iron, walnut grips, small steel screws and springs |

| Dimensions | Barrel approximately 7⅛ in.; typical overall length about 13 in. |

| Artifact Profile | View main artifact page |

2. Photo Documentation

3. Condition Prior to Treatment

The revolver was recovered in 2019 from plowed soil on the Lee family farm near Weatherford, Texas. It arrived at Classic Firearms Restorations in 2025 in an immobile and heavily oxidized state. The frame, barrel and cylinder were covered in thick brown and black corrosion. The cylinder and barrel bores were filled with compact soil. All screws were frozen, the cylinder would not turn, and the loading lever and plunger were locked in place. The original walnut grips were entirely missing and only the grip frame remained.

- Extensive active rust and deep pitting over all exterior surfaces.

- Cylinder, hammer, ring lever and loading lever frozen by corrosion.

- Several screws damaged or immobile; mainsprings and multiple leaf springs broken or missing.

- Grips absent, along with the grip escutcheon and screw.

- Soil and debris compacted in the chambers and barrel bore.

4. Conservation Objectives

The following goals guided the conservation approach:

- Stop active corrosion and stabilize the metal surfaces for long term storage and display.

- Return the revolver to safe mechanical function while retaining honest pitting and field wear.

- Replace structurally missing components such as springs and grips in a clearly documented way.

- Avoid heavy polishing or reshaping that would erase evidence of its recovery and age.

5. Treatment Summary

Over approximately six months the revolver was soaked, cleaned, disassembled and mechanically freed. Long rust-removal and penetrating oil baths were followed by repeated low-voltage electrolysis cycles to lift deeply embedded corrosion. Broken fasteners were drilled out and replaced, new springs were patterned from a loaner Savage Navy, and replacement walnut grips were hand fitted. Final finishing used hot bluing over remaining pitting, with a boiled linseed oil finish on the grips. The revolver was then function tested with percussion caps only.

6. Detailed Treatment Steps

- Initial documentation and photography: The revolver was photographed in its as-found state and key measurements and the serial number 7884 were recorded. Areas of deep corrosion, missing parts and potential structural risk were noted.

- Rust-removal and penetrating oil baths: The gun received an extended rust-removal soak of roughly three weeks, followed by several weeks submerged in penetrating oil to begin loosening internal corrosion and free stuck interfaces.

- Electrolysis cycles: The revolver then underwent repeated electrolysis cycles in a monitored bath. This was the most effective step for lifting heavy oxides from threads, pin joints and the tight clearances of the ring lever action.

- Mechanical disassembly and freeing of parts: Remaining frozen components were released with a jeweler’s saw and careful grinding where necessary, particularly around the cylinder arbor and loading plunger handle. Severely frozen screws were drilled out and replaced with new screws patterned on period dimensions. The plunger bolt was cut for removal and a new bolt was machined and fitted.

- Spring replacement and fabrication: Missing leaf springs and mainsprings were patterned and made by Tim Crowder from an intact Savage Navy revolver loaned for reference. A local blacksmith hardened and tempered the new springs, which were then hand fitted and adjusted for proper tension and timing.

- Surface preparation and bluing: Pitted surfaces were lightly smoothed on a buffing wheel to remove active rust and sharp edges. Metal parts received a hot bluing treatment that evened the color while intentionally leaving historic pitting visible so that the revolver still reflects its time in the ground.

- Grip fabrication and finishing: New walnut grip panels were shaped to match the original profile using the loaner revolver as a guide. A new grip screw and escutcheon were installed. The grips were finished with multiple hand rubbed coats of boiled linseed oil, allowed to cure between applications.

- Reassembly and function check: The revolver was reassembled and lubricated. Cylinder rotation, ring lever cocking, hammer fall and trigger release were function tested with percussion caps only, with no ball or powder. Timing and lockup were found to be correct and reliable.

7. Results and Findings

After treatment, the Savage North revolver is mechanically functional and visually stable while still displaying clear evidence of its long in ground history. The deep pitting that remained after cleaning now reads as honest field and burial wear rather than active decay. The new grips and internal springs restore the revolver to a complete configuration but are fully documented as modern replacements.

- The ring lever mechanism now advances and locks the cylinder forward as designed, and the upper trigger releases the hammer cleanly.

- Corrosion is inactive and the hot blued finish provides a coherent, non gloss surface suitable for display.

- The revolver can be dry fired with percussion caps for demonstration, although live firing is not recommended without a separate safety assessment by a qualified gunsmith.

- Serial range and find location are consistent with documented Civil War era use of Savage Navy revolvers in Texas cavalry units, which adds interpretive value to the piece.

- The revolver was professionally conserved rather than casually refinished. Its current presentation reflects careful work carried out by Mick and Tim Crowder of Classic Firearms Restorations & Iron Will Armory who are noted for their historically sympathetic treatments of antique arms.

8. External Reference

This restoration report is referenced on the Classic Firearms Restorations Project Progress page: www.classicfirearmsrestorations.com/progress